Precision Plastics

Precision Plastics

Service Provided at:

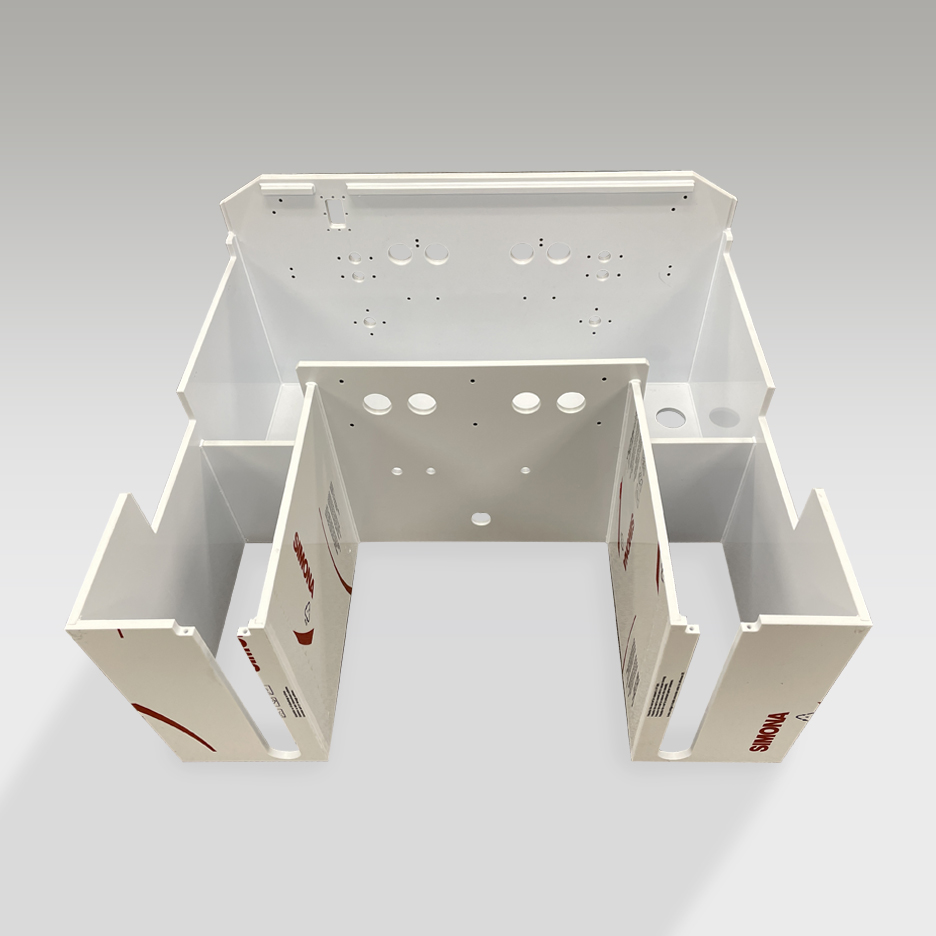

The Plastics division at Group Manufacturing Services has the ability to fabricate polypropylene cabinets, glove boxes, wafer carts, acrylic display stands, display boxes, and more. GMS works with various plastics including polypropylene, polycarbonate, acrylic, Lexan, and Delrin. With the use of a Komo VR512 Router, GMS can fabricate precision plastic parts that can either be welded or fastened together as an assembly.

The Precision Plastics division coupled with the Precision Sheet Metal and Precision Machining divisions make GMS a convenient and affordable one-stop shop for all your products. Having your products assembled at GMS’ facility eliminates costly outsourcing and shortens turnaround time.

Plastic Welding

When assembly is required for your plastic components, GMS has the experience and knowledge to assist you in your selection of the several bonding methods available. Some of the most common boding methods are listed below.

Adhesives

- Cyanoacrylates

- Light-cure Acrylics

- Light-cure Cyanoacrylate

- Epoxies

- Two-part Acrylics

- Hot-melt Adhesives

Welding

- Hot Gas Welding

- Heat Seal

- Freehand Welding

- Speed Tip Welding

- Extrusion Welding

Group Manufacturing takes pride in producing plastic milled complex components with close tolerances. For your convenience, GMS can directly import your already-designed CAD files and commonly offers, but is not limited to, the following plastics:

- ABS

- Delrin/Acetal

- Nylon

- Peek

- Polycarbonate

- Polypropylene

- Teflon

- Ultem

- PVC

- Phenolic/G10