Quality Control

Quality Control

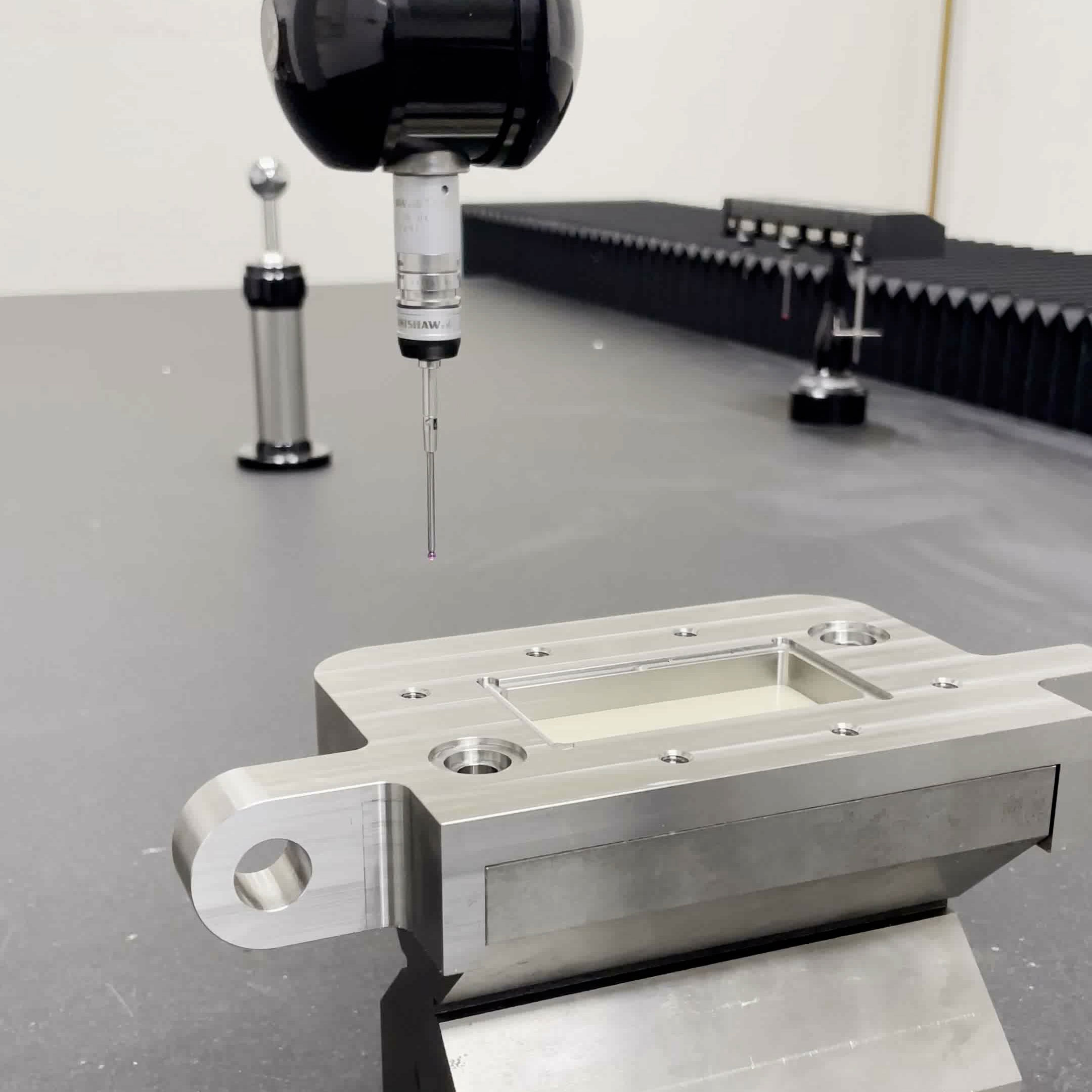

[CMMs] Coordinate Measuring Machines:

CMM machines are used at both facilities and are capable of creating inspection reports to meet your specifications.

- First Article Report

- Final Inspection

- AQL (Acceptance Quality Limit)

Service Provided at:

Group Manufacturing’s San Jose facility is ISO certified. The QC department takes pride in assuring that customers will receive a quality product. To effectively deliver the highest quality product to customers, GMS focuses on quality right from the start. QC technicians perform inspections and tracking procedures on each operation throughout the manufacturing process.

Technicians use automated measuring equipment, such as the Wenzel XO, to insure each part is well within the tolerance specified. The Wenzel XO provides in-depth measuring reports as well as data analysis, and QC technicians are well-equipped to make calibration adjustments if needed. All measuring equipment including machine operator’s tools undergoes ISO traceability calibration on a regular basis.

GMS operates under a strict quality system to efficiently monitor performance in product quality, on-time delivery, customer satisfaction, and department performance. The data that is collected through this system is regularly reviewed by management and used to ensure that goals are being met. It is also used to make improvements in workflow and operations as needed to insure optimum productivity.

Quality Statement

It remains GMS’s goal to supply customers with reliable on-time products and to maintain this goal through continuous improvement of the Quality Management System.

Quality Objective

Group Manufacturing’s objectives are to maintain at least 98% on-time customer requirements, zero customer returns, and 95% first-pass acceptances.